Epoxy Painting of Cooling Tower and Tanks

Premier (C&D) Ltd provide a way to extend the life of many metal based cooling towers and tanks by Epoxy Painting.

Many cooling towers are manufactured of mild steel with a coating placed over them, or alternatively galvanised to protect them from corrosion. However deposition in base of the tower can lead to damage of the surface coating and subsequent corrosion. This corrosion will add to the levels of iron in the system water and eventually can lead to tower failure.

SOLUTION: To minimise the potential for corrosion, or to repair existing corrosion a 2 pack epoxy coating can be applied which effectively seals the metal surface and reduces the corrosion effect thus maximising cooling tower life and also reducing the levels of iron found in the system water.

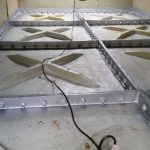

Although composite plastic based water tanks do not have any corrosion in the material, the screws fixing the sections together do as shown below in the photographs. The epoxy coating effectively seals the nuts and bolts and reduces the chance of any iron getting into the domestic water system.

Below are actual photographs taken that show the effect of the corrosion and after the coating is applied. Please click on them to see them enlarged.

To summarise, 2 Pack Epoxy painting is the best way to preserve the life of any metal based cooling tower or tank. Please Contact Premier (C&D) Ltd to arrange a site visit so we can assess if the cooling tower is suitable for paint. If corrosion has not progressed too much, we can fix any holes and gaps that appear before painting.