Cooling Tower Clean and Disinfection

The HSE L8 Approved Code of Practice states that cooling tower clean should be done a minimum every 6 months and that where possible drift eliminators and pack should be removed for cleaning and inspection.

The Premier (C&D) Ltd cleaning regime consists of the following

- Pre-chlorination prior to commencement of cleaning in accordance with HSE L8 guidelines

- Removal, where possible, and cleaning of drift eliminators

- Cleaning of distribution systems

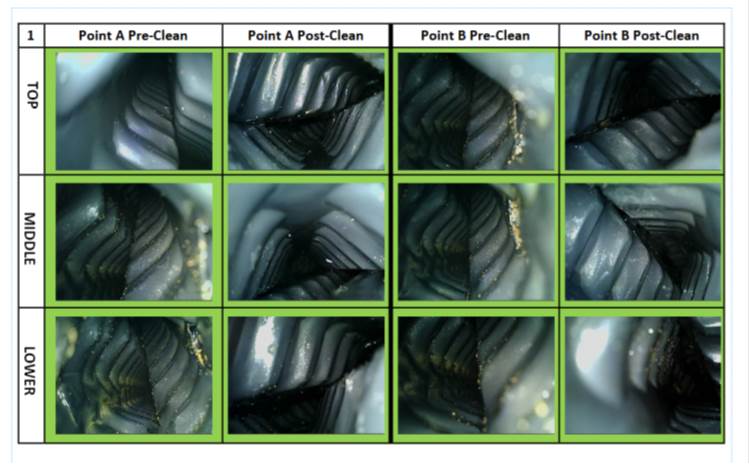

- Removal, where possible, and cleaning of pack. If packing is not removed (or not possible), a Borescope inspection would be recommended (pre and post clean) to be compliant with HSE-L8.

- Draining and cleaning of sump

- Post chlorination in accordance with HSE L8 guidelines

- Written report left on site and a follow up “Cleaning & Disinfection Report” complete with photographs before and after clean produced

Borescopic Inspections

Where removal of the packing is not possible or due to time constraints, a borescopic inspection report can be a way to demonstrate that the packing is in a satisfactory condition and also satisfy HSE-L8 requirements.

Borescope inspections are recommended to be done at least yearly to monitor the condition of the packing and this enables the client to plan ahead if any action is required (ie. packing replacement, acid clean etc.).

The borescope report consists of

- Summary of Legionnaires disease: Approved Code of Practice (ACOP L8) and Technical Guidance (HSG274)

- Equipment used for Borescopic inspection.

- Cooling Tower description and access methods.

- Location of points where pictures were taken in the packing.

- Picture Report which uses cell colours to determine the approximate condition of the packing (using guidance from the Appendix).

- Summary of any findings in the pictures.

- Appendix including action levels and example pictures for guidance.